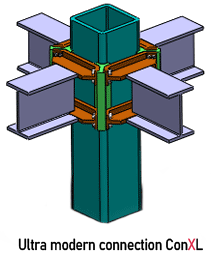

CONXL CONNECTIONS

DETAILS OF CONXL JOINT

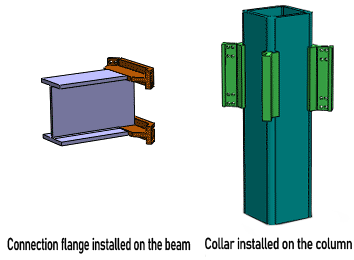

ConXL connection is designed and presented to achieve a tight and safe joint, eliminating shop-welds and easy installation. It is a moment connection of wide flange beams to HSS or a built-up box column. Collar is an external main section of this connection, consists of steel flange and web that is welded to beam flanges in the factory previously (via complete joint penetration (CJP) groove welds) and it is produced by forging method.

This section transfers forces. Connection flange which is welded at the top or bottom of the beam and attached to collar with bolt also is produced by forging method. This connection is applicable to special and intermediate moment frames.

ConXL connection is designed and provided for reaching to a tightened and safe joint through omission of workshop weld and easy installation. This connection is composed of some parts called “Collar” which are installed in four corners of column. Based on this method, beams are attached to that by a pair of joint flange (the same as picture).

Collar is the main part of this connection which is produced by Forging Method. The duty of load transfer is up to this part. The connection flange too, which is welded to top and bottom of beam and linked to collar with a bolt, is manufactured by this method. For making a ConXL connection, collars will be installed and welded with very high precision.

HISTORY OF CONXL

ConXL system is a structural connection system with modern technology which is based on medullar chassis. For the first time, it was introduced by expert engineer called Robert Simon who has been active for more than 30 years in construction industry, for the purpose of execution types of steel structures including: residential, industrial, commercial, petrochemical, oil and gas, hospitals, multi floor parking, shopping centers, data center structures along with vital and infrastructure ones like laboratories and important research centers.

Mr. Simon thought about creating systems and methods for designing, manufacturing and execution of steel structures since years ago especially after terrorist attack of September 11th to twin towers of the world trade center situated in Newyork which made both completely collapsed. His purpose was increase execution speed and mass production of high quality buildings which are wind and earthquake proof, safe from explosion and collapse, and at the same time affordable. In this regard, he established CONXtech Co. in U.S.A for the purpose of putting his ideas into practice.

About CONXtech Company

By years of studying, research and passing 17 tests of seismic tests with complete scale on his created system(ConXL structural joint) in the university of Arizona along with precise technical studying by CPRP of AISC 358 (American Institute of Steel Corporation), CONXtech Co finally was succeeded in receiving confirmation for ConXL on March 19th , 2010. Also, by use of its abilities could entered into AISC 358 in the form of code in order to be used globally in seismic design for steel frame resisting moment intermediate and steel frame resisting moment special.

The Constituent of ConXL Joint

Steel structures with ConXL connection systems are made of three parts:

1- Box Columns Built-up filled with concrete or HSS= 40*40 cm;

2- Column Collars; each corner of column is dedicated a collar (it has three parts) which is joint by a strip weld

3- Wide flange beams together with connected collar to their head and end.

Details of ConXL Joint

ConXL Joint is designed and introduced with the purpose of reaching to a tighten joint through omitting the necessity of workshop weld and easy installation. It is composed of parts called Collar which are installed in four column corners. Beams are connected by a pair of flange (below picture).

Advantages of ConXL:

1- ConXL system is a connection with 6 degrees restrain (X,Y, Mz, My & T)

2- It makes steel structures needles of welding at the place of execution and all welding are done under controlled conditions in the factory;

3- It needs less than 2 weeks for execution unlike popular structures which take few months;

4- It has lower and locking joints which decrease the structure risk;

5- It benefits from adequate strength against earthquake, explosion, falling objects based on related test. This system has the certification from AISC, AFTP, OSHPD, UFC.

6- It is prefabricated (more than 80%) which is considered as one of its most important characteristics;

7- It can be used for constructing daily 900 structure;

8- It does not waste material as its parts are manufactured in the factory;

9- It is especially suitable for particular steel structures with large opening (5.5-20 m). Therefore, it can be used in constructing industrial and commercial buildings

10- It makes structure executing faster, better and safer than popular systems

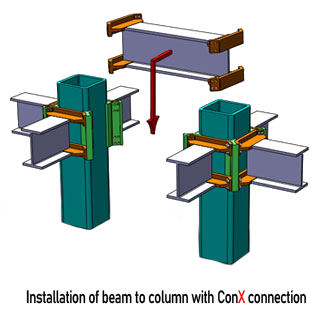

How to Execute ConXL Joint

1- Transportation of parts to the place of project; first all manufactured parts including columns, attached collars, wide flange beams with connector plate will be transported to the project place based on related regulation

2- Installation of columns at the place of base plates; if substructure is executed and base plates are installed too, then box column with attached collars will be put at the position of base plates by crane. After making sure of being plumbing and to be along with considered coordinate axes, welding will be done and they will be attached to the base plate.

3- Installation of beams; after installation of columns and making sure from their temporary stagnation during constructing the structure, each of beams will be positioned at the related axis between two columns by means of crane. By ConXL joint, the attached collars to the beam flange will be put easily and without special tools and in gravitational mode in the grooves embedded in column collar. Then they will be tightened by joints.

ConXL system requirements and limitations

- Requirements

Beams

- Beams shall be rolled wide-flange or built-up I-shaped members.

- Beam flange width shall be limited to a maximum of 300 mm.

- Beam flange thickness shall be limited to a maximum of 25 mm.

- By using the elements of built-up I-shaped columns, the minimum size of the fillet welds shall be the lesser of 8 mm and the thickness of the column web.

- The clear span-to-depth ratio of the beam shall be limited as follow:

- For IMF systems, 5 or greater

- For SMF systems, 7 or greater

Columns

- Columns shall be square 406 mm, HSS sections or square 406 mm.

- Column dimension shall not be less than 400 mm.

- Column wall thickness shall not be less than 10 mm. (Column wall thickness for HSS columns shall not be less than 10 mm nominal).

- Columns shall be completely filled with structural concrete having unit weight not less than 110 pounds per cubic foot (17kN/m3). Concrete shall have 28-day compressive strength not less than 3000 psi (21 MPa)

Connection components

- Collar forgings shall conform to the requirements of Appendix B, Forging Requirements. Raw material shall conform to the requirements of ASTM A 572.

- Collar flange bolt holes shall be 3 mm larger than the nominal bolt diameter. Bolt holes shall be drilled.

- The bolts used in the ConXL connection are 31.8 mm diameter ASTM A574. These bolts are similar in chemistry and mechanical properties to ASTM A490 bolts, but have socket heads to accommodate their use in this connection.

Others

- In accordance with the restrictions put by 2800 earthquake bylaw and depends on kinds of seismic design of special and intermediate moment frames, number of stories by means of this system are 15, 50 and 150 meters.

- Maximum of spans length for constructing structures with this system is 12 and for non-building structures is 20 meters.

- Limitations

Construction limitations

- Collars should be manufactured by special factories, which is so expensive.

- All welding should be done in controlled factory environment.

- ConXL connections may be used to provide moment connections to columns in orthogonal frames. All moments beams connecting to a ConXL node (intersection of moment beams and column) must be of the same nominal depth.

Design limitations

- Because collars necessarily should execute in four sides, therefore in cases which column is placed in the corner and the connection is planar, the project or structure becomes non-economic.

- Due to this connection is an integrated system and also a kind of external diaphragm, collar corner and collar flange installation of planar or trimorphous connections cause collar protrusion on sides of the building and architectural limitation.

Standards and Regulations

In 2010, AISC founder, has examined the ConXL connection and published it after confirmation. Chapter 10 of this regulation is dealt this connection in detail which can be downloaded through this link.