خطوط نورد فولاد ماشین نکا

Foolad Machine Industries has started its professional activities by manufacturing industrial machinery and so far, most of its machines are designed and produced through relying on the several year knowledge and experience which company achieved.

Company’s strategy has always been to help the country to be needless of foreign products through industrial localization in addition to development of science and technology.

This company has the ability to design and manufacture various production lines of machinery by having experienced engineering staff, skilled and well-trained technicians and by means of modern industrial machines including CNC milling, lathe and CNC shear machines.

The most important achievements of the company are as follows:

• Designing and manufacturing rolling mill line for heavy structural steels, with capability of producing structural steel sections with different dimensions and wall-thicknesses.

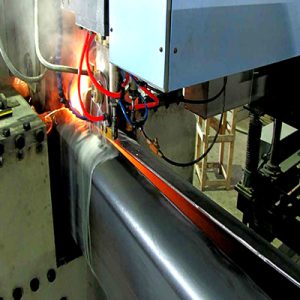

• Designing and manufacturing rolling mill of ERW pipes with capability to produce different sizes.

• Designing and manufacturing industrial machinery (guillotine, punch, shear machine, …) .

• Designing and manufacturing overhead cranes.

NEKA MACHINE STEEL COLD ROLLING LINES

20"

Production of 20-inch pipes and rectangular profiles (square and rectangular) with maximum cross-sectional dimensions of 450x450 up to 15 mm thick and with an output of 80,000 tons

14"

Production of 14-inch pipes and rectangular profiles (square and rectangular) with maximum cross-sectional dimensions of 300*300 up to a thickness of 10 mm and with an output of 60,000 tons.

12"

Production of 12-inch pipes and rectangular profiles (square and rectangular) with a section of 260*260 to 300*220 up to 8 mm thickness and an output of 40,000 tons.

4"

Production of 2 to 4-inch pipes and 40*40 to 90*90 profiles, with a thickness of 5 to 10 mm and an output of 24,000 tons.5 to 10 mm thickness

2"

Production of pipes up to 2 inches and profiles from 20*20 to 50*50, with a maximum thickness of 4 mm and an output of 5000 tons.

Direct method

Production of rectangular sections (square and rectangle) in dimensions 200*200 to 400*400 and thickness 4 to 15 mm and an output of 70,000 tons